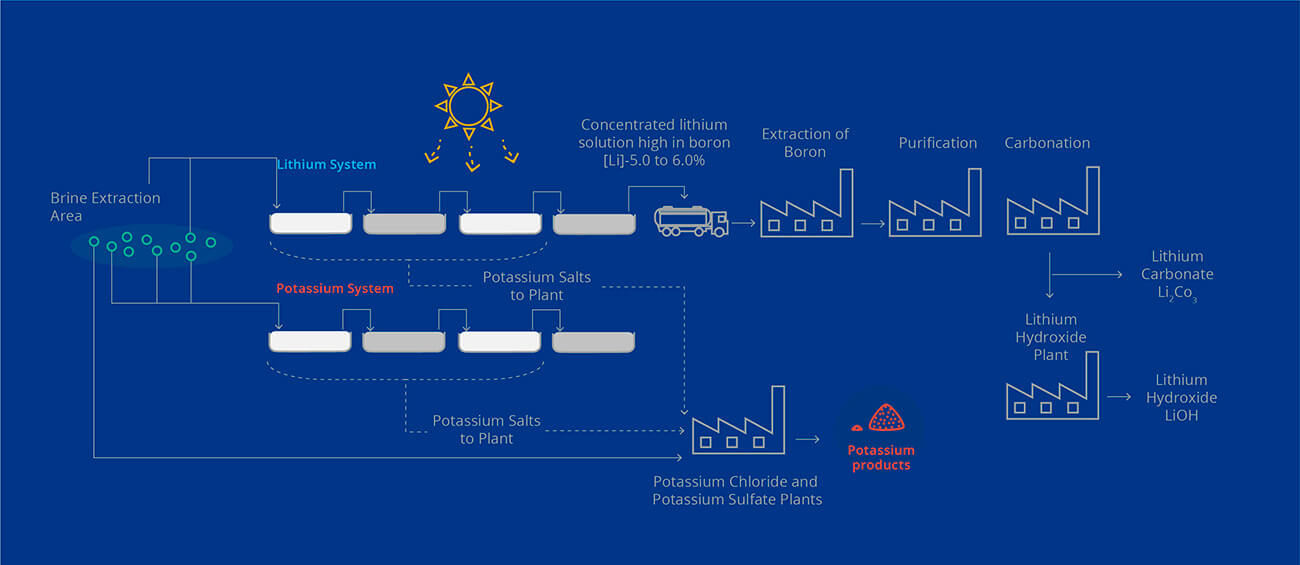

Our lithium extraction process in the Salar de Atacama is environmentally friendly and focuses on the sustainable development and production of lithium. By concentrating lithium solutions and depositing by saturation and gravity, without the use of external substances, eliminating most of the other elements and reaching an approximate concentration of 6% lithium, 30 times more concentrated than the extracted brine.

This stage of the process lasts more than a year, and most of the energy used corresponds to solar energy, approximately 95,8%. When lithium reaches the desired concentration, this solution is sent to the chemical plant located in the Salar del Carmen, on the outskirts of the city of Antofagasta, where lithium carbonate and lithium hydroxide are produced.

To learn about our entire sustainable lithium extraction and production process at SQM, we invite you to read our report on sustainable lithium production in Chile.